|

|

|

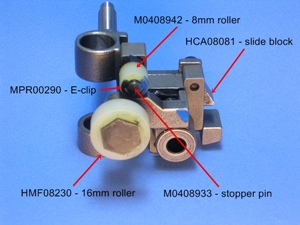

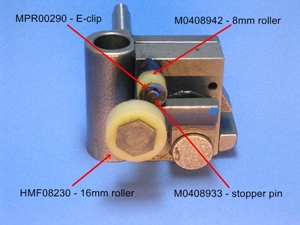

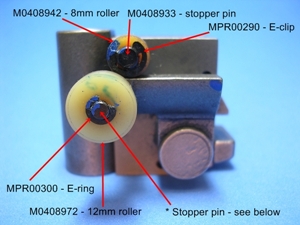

Happy Embroidery machines use two different parts, depending on the model. Look at your parts manual or consult with your parts dealer for the correct replacement parts.

|

|

Reciprocator |

Needle bar Driver |

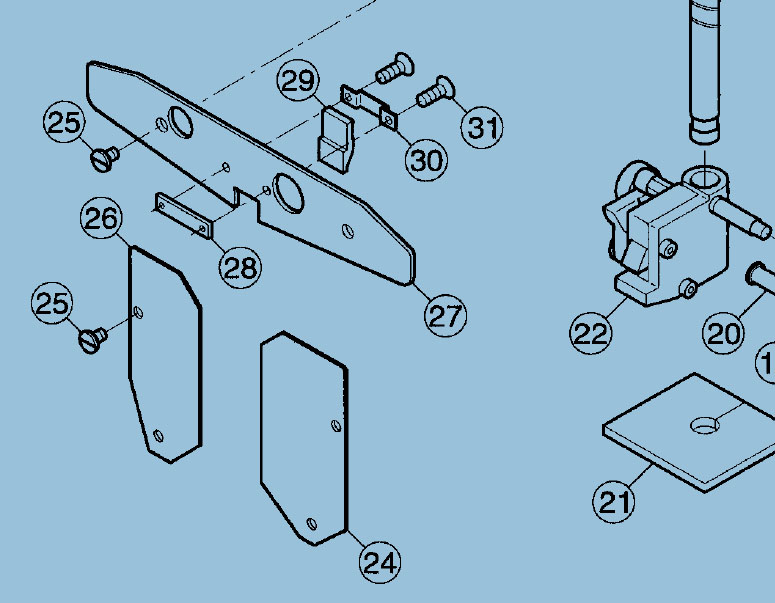

NOTE: The photo and parts numbers shown may not be for your machine. Please confirm the parts numbers with your parts supplier before ordering.

|

|

HCA-08022 smallHappy Needle Bar Driver:

|

|

|

HCG-08110 smallHappy Needle Bar Driver:

|

|

|

M04-08276 smallHappy Needle Bar Driver:

|

Upper Face Plate:One other thing that you may want to have on hand for some models of Happy machines is a Cushion B shown in the diagram as part number 29. Cushion B may be black or white in color. If you are ordering one of these you may want to get parts 28, 29, 30, and two screws, part 31s.

Example:

|

|